The Role of Injection Molding in Creating Implantable Medical Devices

Injection molding is revolutionizing the production of implantable medical devices, allowing for customized plastic molding that meets the unique requirements of this critical segment. In this article, we explore the significance of injection molding in the manufacturing of implantable medical devices, with a focus on how injection parts companies are shaping the industry.

Customized Plastic Molding: Precision Engineering for Implantable Medical Devices

Customized plastic molding techniques empower injection parts companies to create implantable medical devices with exceptional precision, ensuring a perfect fit and optimal functionality. By leveraging advanced design and manufacturing capabilities, precise and complex geometries can be achieved, enabling the production of customized devices tailored to individual patient needs.

Sterility and Safety: Ensuring Compliance in Implantable Medical Devices

Sterility and safety are paramount when it comes to implantable medical devices. Injection molding plays a critical role in ensuring compliance with rigorous quality standards, as it allows for the creation of hermetically sealed and biocompatible devices that minimize the risk of infection, rejection, or adverse reactions.

Versatility and Material Selection: Meeting the Demanding Requirements for Implantable Devices

Injection molding offers immense versatility when it comes to material selection for implantable medical devices. With a vast range of medical-grade materials available, including biocompatible polymers and metals, injection parts companies can select the optimal material that provides the required strength, durability, and biocompatibility for each specific medical device.

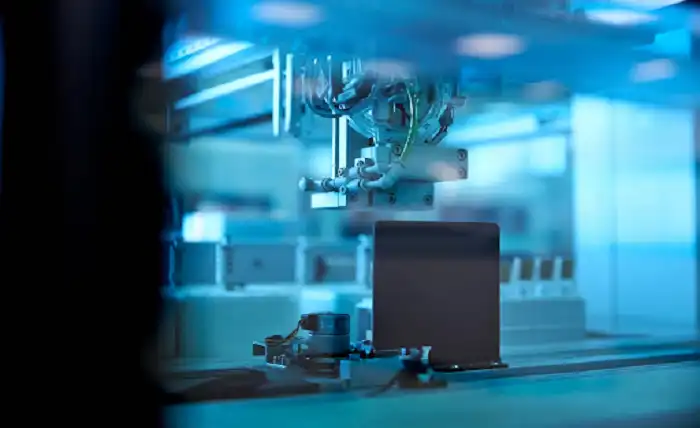

Precision and Consistency: Advanced Manufacturing Techniques for Implantable Devices

Advanced manufacturing techniques, such as automation and robotics, have revolutionized the production of implantable medical devices through injection molding. These techniques ensure precision, repeatability, and consistency, enabling injection parts company medical to produce high-quality devices that meet strict specifications within shorter production cycles.

Regulatory Compliance and Quality Assurance in Implantable Medical Device Manufacturing

Manufacturers of implantable medical devices must adhere to stringent regulatory guidelines and quality standards. Injection parts companies play a pivotal role in ensuring compliance by adhering to practices such as cleanroom manufacturing, strict process controls, and comprehensive quality assurance protocols to guarantee the safety and efficacy of implantable devices.

Conclusion

Injection molding has transformed the production of implantable medical devices, enabling injection parts companies to provide customized plastic molding solutions that meet the exacting demands of this critical field. Through precision engineering, adherence to stringent safety and sterility requirements, versatility in material selection, advanced manufacturing techniques, and unwavering commitment to regulatory compliance and quality assurance, injection parts companies are driving innovation in the development of reliable, safe, and effective implantable medical devices.