Understanding the Hollow Fiber Spinneret: Innovation at the Core of Fiber Technology

In the realm of advanced manufacturing and material science, hollow fiber spinnerets play a pivotal yet often overlooked role. These specialized devices are essential in the production of hollow fibers—microscopic tubes with applications ranging from water filtration to medical devices and even aerospace engineering. This blog post explores what hollow fiber spinnerets are, how they work, their applications, and why they are so important in modern industry.

What Is a Hollow Fiber Spinneret?

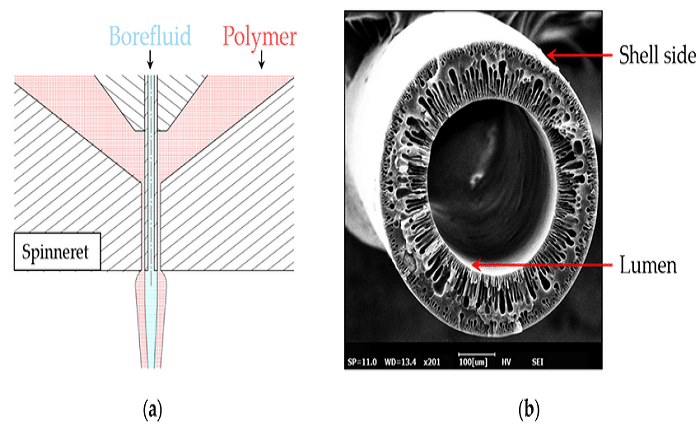

A hollow fiber spinneret is a precision-engineered tool used in the spinning process to create hollow fibers. Unlike solid fiber production, where a single stream of polymer is extruded through a hole, hollow fibers are produced by extruding polymer around a core material—usually a gas or liquid—through a specially designed nozzle.

This nozzle, the spinneret, is designed with concentric channels to enable simultaneous extrusion of the polymer and the core material. As the polymer solidifies, typically through air cooling or a coagulation bath, it forms a tubular fiber around the core. Once the core material is removed or retained, what remains is a hollow structure.

Why Hollow Fibers?

Hollow fibers have a central channel, much like a straw, which provides them with several unique advantages:

- High surface area to volume ratio – Ideal for applications requiring exchange of substances, like filtration or gas separation.

- Lightweight yet strong – The hollow core reduces weight while maintaining structural integrity.

- Efficient transport properties – Fluids or gases can move through or along the fiber, making them effective for dialysis, artificial lungs, and chemical separation.

Because of these properties, hollow fibers are widely used in industries ranging from healthcare to energy.

The Anatomy of a Hollow Fiber Spinneret

Designing a hollow fiber spinneret requires an understanding of fluid dynamics, material science, and mechanical engineering. Here’s a breakdown of its main components:

- Outer Orifice: This is the circular opening through which the polymer exits. It defines the outer diameter of the fiber.

- Inner Needle (or Capillary): Positioned concentrically within the spinneret, this needle delivers the core material (often air or a different liquid).

- Polymer Inlet: Connects to a reservoir or pump delivering molten polymer or polymer solution.

- Bore Fluid Inlet: Supplies the core fluid that forms the inner channel of the hollow fiber.

The key to successful hollow fiber spinning lies in maintaining proper alignment and flow rates between the core and shell materials. Any imbalance can result in collapsed or inconsistent fibers.

How Hollow Fiber Spinnerets Work

The process of hollow fiber spinning using a spinneret involves several steps:

- Polymer Preparation: A polymer (such as polysulfone, polyethersulfone, or cellulose acetate) is dissolved in a solvent to form a viscous solution.

- Feeding the Spinneret: The polymer solution is fed into the spinneret through the outer channel, while a bore fluid (e.g., water, air, or another immiscible liquid) is simultaneously introduced into the central needle.

- Extrusion: The materials are extruded through the spinneret tip. The polymer coats the bore fluid, forming a double-layer stream.

- Solidification: As the stream exits the spinneret, it enters a coagulation bath (wet spinning) or is cooled in air (dry spinning), solidifying the polymer and forming a hollow fiber.

- Post-processing: The fibers may undergo washing, drying, or chemical treatment depending on the end application.

Key Applications of Hollow Fiber Spinnerets

The versatility of hollow fibers has led to their adoption in many critical industries. Here are some of the most impactful:

- Water Filtration and Desalination

Membranes made from hollow fibers are at the core of reverse osmosis and ultrafiltration systems. These systems remove salts, bacteria, and other impurities from water, making it suitable for drinking, industrial use, or agriculture.

- Medical Applications

Hollow fibers are used in artificial kidneys (dialyzers) for patients with renal failure. Their unique structure allows for the efficient exchange of waste and electrolytes between blood and dialysis fluid.

They are also used in:

- Artificial lungs

- Drug delivery systems

- Tissue engineering scaffolds

- Gas Separation

Industries use hollow fiber membranes to separate gases like oxygen, nitrogen, and carbon dioxide. These systems are used in everything from scuba tanks to carbon capture technologies.

- Textile and Smart Fabric

While more niche, hollow fibers are also used in textiles for thermal insulation, moisture management, and even embedding electronics.

- Biotechnology and Research

Laboratories use hollow fiber bioreactors for growing cells and producing biological products such as monoclonal antibodies and vaccines.

Materials Commonly Used in Hollow Fiber Production

The choice of material depends on the application. Here are some widely used options:

- Polysulfone (PSU): Excellent thermal and chemical resistance, often used in medical and filtration devices.

- Polyethersulfone (PES): Similar to PSU but with better hydrophilicity.

- Polyvinylidene fluoride (PVDF): High chemical resistance, used in harsh environments.

- Cellulose Acetate: Biodegradable and often used in hemodialysis.

The spinneret must be designed to accommodate the rheology (flow behavior) of these materials.

Innovations and Future Trends

As industries demand more efficient and durable materials, the design of hollow fiber spinnerets continues to evolve:

- Micro and Nano Spinnerets: Precision manufacturing now allows for fibers with diameters in the nanometer range, useful in drug delivery and nanofiltration.

- Multi-bore Spinnerets: These advanced designs can produce fibers with multiple hollow cores, expanding the surface area and functionality.

- 3D Printed Spinnerets: Additive manufacturing enables rapid prototyping of custom designs, reducing cost and development time.

Additionally, AI and machine learning are beginning to play a role in optimizing spinneret design and production parameters.

Conclusion

The hollow fiber spinneret may not be a household term, but its impact spans countless industries and critical technologies. From purifying water to saving lives with medical devices, the precision engineering behind spinnerets enables the creation of fibers that are both tiny and incredibly powerful.

As innovation continues to push the boundaries of what materials can do, hollow fiber spinnerets will remain at the forefront of progress—quietly shaping the fibers of our future.