Step-by-Step: Inspecting Internal Components of Williams Engines Using a 4 mm Videoscope

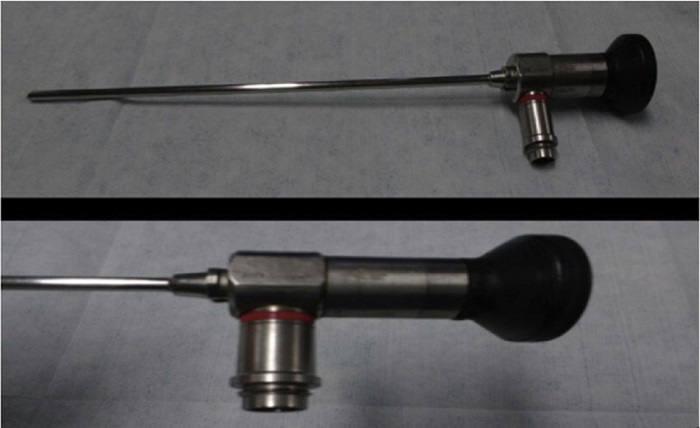

The maintenance method for an aeroplane engine must be precise, reliable, and efficient. For technicians working on Williams engines, maintaining these standards requires advanced inspection tools that deliver clear, accurate visuals of internal components without the need for disassembly. Among the most effective instruments in this regard is the Borescope for Williams engine, particularly the 4 mm videoscope, which offers a perfect balance of size, flexibility, and high-resolution imaging.

The Importance of a 4 mm Videoscope

Williams engines are compact, high-performance power units commonly used in light jets and UAVs. Their intricate internal design makes traditional visual inspection methods difficult, time-consuming, and costly. This is where a 4 mm videoscope becomes invaluable. Its slim profile allows technicians to navigate narrow channels within the engine and examine components such as turbine blades, combustion chambers, and compressors without dismantling major sections. Being able to take both live video and still pictures makes sure that the state of the engine is accurately assessed and recorded.

Step 1: Preparing for Inspection

Before beginning any inspection, technicians must ensure that the engine is cool, properly grounded, and clear of any debris. The 4 mm videoscope should be checked for functionality, ensuring the camera lens is clean, the articulation works smoothly, and the light source provides even illumination. The Borescope for Williams engine should also be calibrated if the model allows, to guarantee accurate color representation and focus during examination.

Step 2: Accessing the Inspection Ports

Williams engines come with several designated borescope ports that give access to internal sections. These ports are strategically located to provide a clear path to key areas such as the fan, turbine, and compressor stages. Using the correct access point ensures a safer and more efficient inspection. Technicians insert the videoscope carefully through these ports, avoiding contact with sensitive internal surfaces.

Step 3: Navigating Internal Components

Once the 4 mm videoscope is inside, the live feed on the connected display allows the operator to steer the tip toward specific components. With multi-directional articulation, technicians can adjust the view angle to inspect surfaces for signs of wear, pitting, cracks, or foreign object damage. The compact diameter of the 4 mm probe enables smooth navigation through tight spaces that larger scopes cannot reach. Each finding should be documented with still images or video clips for record-keeping and later analysis.

Step 4: Evaluating Engine Health

After visual access is achieved, technicians analyze the images for surface irregularities, carbon build-up, or heat-related deformation. Any visible damage should be cross-referenced with maintenance guidelines provided by the engine manufacturer. The data collected using the Borescope for the Williams engine helps determine whether a component requires cleaning, repair, or replacement. Consistent use of a videoscope during scheduled maintenance improves the long-term performance and safety of the engine by allowing early detection of issues before they escalate.

Step 5: Post-Inspection Procedures

Once the inspection is complete, the videoscope should be retracted slowly to prevent any accidental contact with engine components. All collected footage and photos should be archived as part of the aircraft’s maintenance records. Proper care of the videoscope, including cleaning the lens and storing it in a protective case, extends its lifespan and ensures accurate results in future inspections.

The Value of Regular Videoscope Inspections

Regular borescope inspections are essential to maintaining the operational integrity of Williams engines. By integrating this process into scheduled maintenance routines, aviation professionals can prevent unexpected engine failures, minimize downtime, and reduce costly overhauls. The precision of a Borescope for Williams’ engine ensures every inspection is efficient, consistent, and compliant with aviation safety standards.

Final Thoughts

Using a 4 mm videoscope simplifies the complex process of inspecting Williams engines. It empowers technicians to identify hidden issues, enhance operational reliability, and maintain optimal engine performance with minimal disruption. As aviation technology continues to evolve, tools like the 4 mm videoscope remain a cornerstone of modern engine maintenance—ensuring every aircraft powered by a Williams engine operates with maximum safety and efficiency.