The discovery of the first robotic arms in industrial settings was a significant milestone that tremendously accelerated the development of automation. Also called Unimate, this first industrial robot ever invented by man was precisely made to help in the manufacturing processes much before the 1960s and 1970s era. The Unimate revolutionized production techniques and started the flow, which resulted in robotics innovations in the future. This article explores the functionalities of the first robotic arm and its relevance in industrial operations.

Historical Development of Unimate

The Unimate was devised by the inventor George Devol and the entrepreneur Joseph Engelberger, the latter being the one who had, in 1961, brought the Unimate into the consumer mass market. The concept may have evolved in the 1950s, and the first model was successfully developed in 1961. The General Motors factory in New Jersey was the first one to introduce such cutting-edge technology, exploiting it through diecasting and welding duties. Unimate’s introduction demonstrates a new era in industrial automation. Robots can perform monotonous and dangerous tasks precisely and reliably, which is a futuristic way.

Mechanical Design and Structure

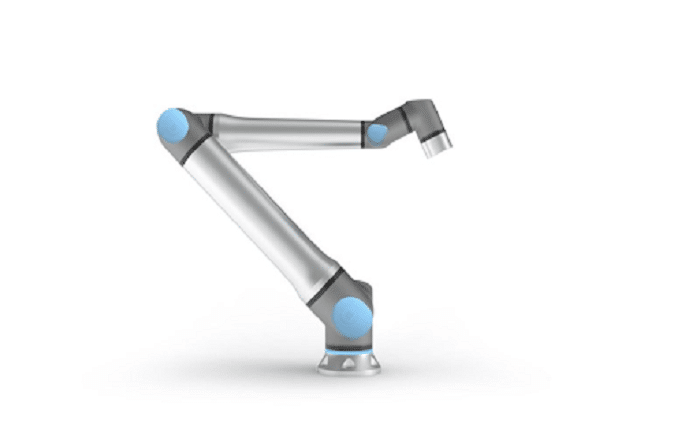

The first robotic arm was built by a man with vision and a genius in mechanical engineering. The Unimate was designed in a way that made it solid and straightforward, with arms that were composed of a group of joints and links that replicated the movements of a human arm. Hydraulic actuators were used to power it, which helped the machine produce the needed force and precision for industrial tasks. The arm would have the potential to sway and rotate along different axes so that it could apply to other tasks and areas.

Degrees of Freedom

The degree of freedom of Unimate was one vital aspect that enabled the arm to execute a variety of movements collectively. The robot’s first arm was a six-coupled articulated mechanism, able to move in a variety of directions and even carry out most tasks. This kind of agility was crucial for its role in manufacturing, which required changing direction often and trying different positions to complete various operations.

Programming and Control

The algorithms and automation of the first robot that worked in the industry were new ideas back then. The Unimate, the first robot designed by George C. Devol and marketed by Decloitre and Company, used a magnetic drum memory system to store instructions that could be reprogrammed to carry out multiple tasks. This would be accomplished by the operator instructing the robot on the sequence of movements and orders, which would then be carried out. Showing this ability to be reprogrammed turned out to be a milestone since a single robot is capable of operating in different ways at the factory, which improves its utility.

Automation and Efficiency

Among the most innovative uses of robots in the automotive industry is definitely the introduction of the first arm robot that increased automation and efficiency significantly. Unimate always works nonstop and is not subject to fatigue or erroneous operation, which subsequently increases the manufacturing processes’ output and accuracy. This degree of efficiency had been inconceivable before the advent of robotics, and labor needed to stand a chance with human energy, thus highlighting the vast potential of industrial robotics.

Safety and Hazard Reduction

One of the leading causes of the production of the first industrial robot was not only to create a safer work environment but also a more productive workplace. Unimate did it because humans cannot be put in danger or perform tedious tasks as they handle hot metal in diecasting. It was the robot’s arm that was responsible for all the dangerous jobs. In this way, the robotic arm was a significant factor in the reduction of risk for the employees and an improvement in workplace safety in general.

Impact on Labor

Although the introduction of Unimate raised the fear of job loss, it also generated new levels of employment for people in skilled jobs. The demand for robot replacement parts, programming, and supervision created the need for new robotics and automation-related job categories. Thus, though implementations are frequently referred to as “automation” of certain tasks, the technology also contributes to the maturation of the labor market.

Legacy and Influence on Modern Robotics

Therefore, it laid a cornerstone in the construction of today’s robotics. Its success polished the path for future developments and integration of robots into the industry, which also encouraged a lot of research and innovation in the area. Much in the same way that their robotic counterparts of today are imbued with complex sensors, artificial intelligence, and above-average mechanical capabilities, all of these can be traced back to the origins of Unimate.

Evolution of Industrial Robots

What began with the era of the first industrial robot has since been a field of robotics that has seen numerous developments. Contemporary robotic arms are applied in different fields of industry, e.g., automotive manufacturing, and healthcare, and usually have super precision to carry out the mart tasks. The principles set up by the first robot, Unimate, kept inspiring the new designs in robotic engineering.

Conclusion

The invention of Unimate, a robotic arm, was a landmark in the industrial era, and it demanded the transformation of the production process. This benchmark is defined by its key attributes, such as mechanical design, degrees of freedom, programming capacity, and safety features, and it serves as a standard for future developments of robotic devices. Removing the need for tedious and dangerous jobs, an industrial robot that was the first ever to be mechanized achieved a large amount of efficiency and safety in the single process of manufacturing. Unimate, the first robot, began an evolutionary process of field robotic technologies we see today. It signifies its first step in the automation of industry.