Printed Circuit Board Assembly (PCBA) is a critical process in the electronics manufacturing industry. It involves the assembly of electronic components onto a printed circuit board (PCB) to create functional electronic devices. This article delves into the PCBA process, highlighting the steps involved, the technologies used, and the importance of this process in the modern manufacturing landscape.

What is PCBA?

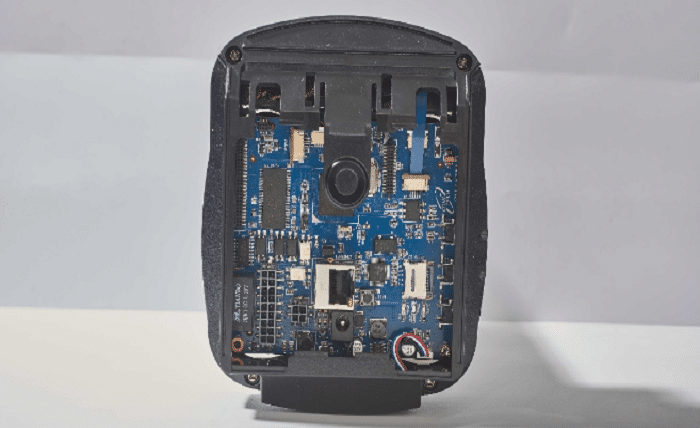

PCBA stands for Printed Circuit Board Assembly, which is the process of soldering or assembly of electronic components to a PCB, a board that holds and connects these components. The PCB itself is often created through a separate process involving multiple layers of material that are etched and laminated together. Once the PCB is prepared, components like resistors, capacitors, transistors, and integrated circuits are attached to form a functional electronic assembly.

Key Steps in the PCBA Process

- PCB Design and Manufacturing: Before any components can be assembled, the PCB must be designed using CAD software to layout the circuit schematically. The design is then transformed into a physical board through processes such as etching and drilling.

- Component Sourcing: Acquiring the electronic components necessary for the assembly is a critical step. These components must meet the specifications detailed in the PCB design.

- Solder Paste Stenciling: Solder paste is applied to areas of the PCB where components will be placed. This is typically done using a stencil that ensures the paste is applied precisely where needed.

- Pick and Place: Components are placed on the PCB using automated equipment that accurately places them according to the PCB design.

- Reflow Soldering: Once components are placed, the PCB passes through a reflow oven where the solder paste is melted, and then it cools to form a solid bond between the components and the board.

- Inspection and Quality Control: After soldering, the boards are inspected for any potential soldering defects using methods like Automated Optical Inspection (AOI) and X-ray inspection.

- Testing: Functional tests are performed to ensure the assembled PCB works as intended. This may involve in-circuit testing, power-on testing, and other functional verification procedures.

- Final Assembly: Additional mechanical assembly, such as attaching heat sinks, enclosures, or connecting cables, might be required to complete the manufacturing process.

Technologies Used in PCBA

The PCBA process utilizes various technologies to enhance efficiency and accuracy. These include:

- Surface-Mount Technology (SMT): Enables the mounting of components directly onto the surface of the PCB, allowing for more components per unit area and typically results in higher performance products.

- Through-Hole Technology (THT): Involves inserting component leads into holes drilled in the PCB. This method is often used for components that require stronger physical connections.

- Automated Optical Inspection (AOI): A non-contact test method used to visually check for placement and soldering defects.

- Selective Soldering: Allows for the application of solder only where it is needed on the board, reducing waste and improving precision.

Importance of PCBA in Manufacturing

PCBA is fundamental to the electronics manufacturing process as it directly influences the performance and reliability of the final product. As electronic devices become smaller, more powerful, and more integrated, the precision and quality of PCBA have become increasingly critical. Industries ranging from consumer electronics to aerospace depend on sophisticated PCBA to deliver products that meet stringent performance and reliability standards.

Conclusion

Printed Circuit Board Assembly (PCBA) is a complex and essential process in the production of electronic devices. From initial design to final testing, each step in the PCBA process is crucial for ensuring the functionality and reliability of electronic products. As technology advances, the PCBA process continues to evolve, incorporating new technologies and methodologies to meet the growing demands of modern electronics. The continuous improvement in PCBA processes and technologies is vital for keeping pace with innovations in the electronics industry.